Nanoprom Chemicals S.r.l.

Description

NANOPROM is a pioneer company in the research and industrial application of nanomaterials.

Since the late ’90s, the company has been active in the research field of silica-based nanomaterials.

Referring to the area of surface protection has played an innovative role in the development of Polysil®, covered by several international patents.

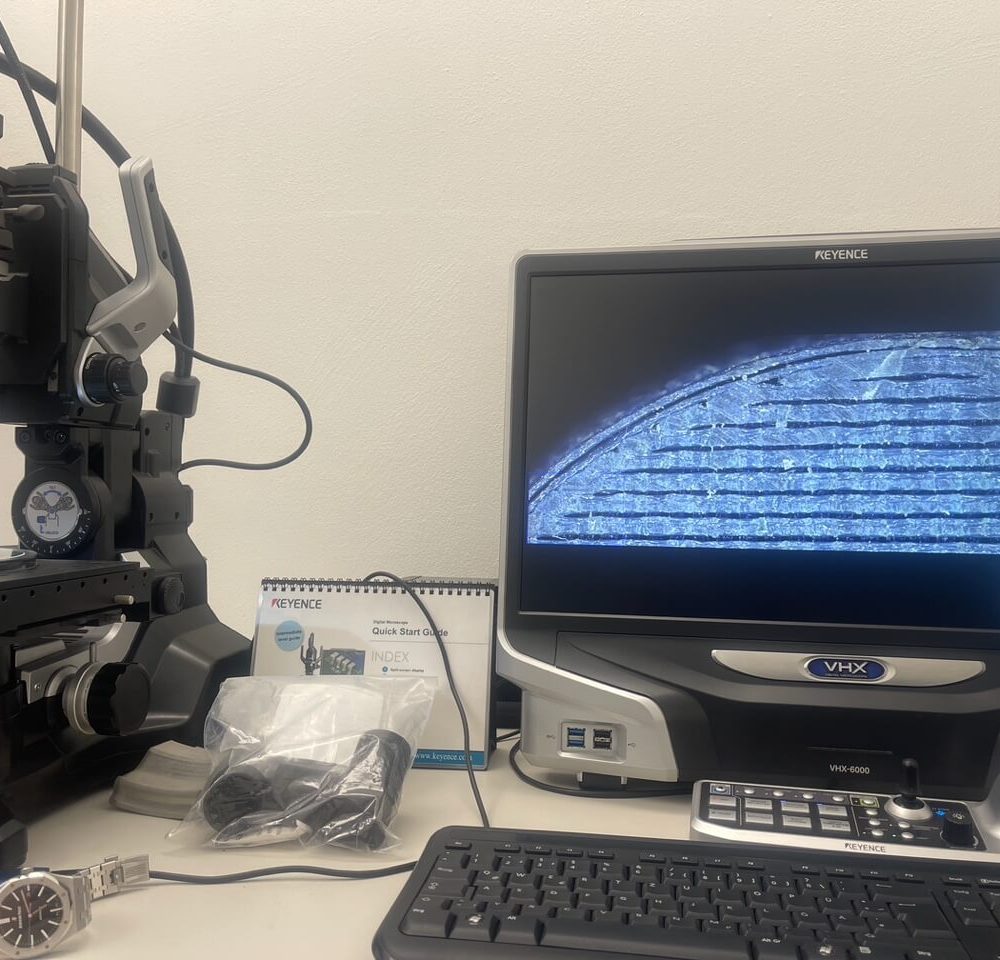

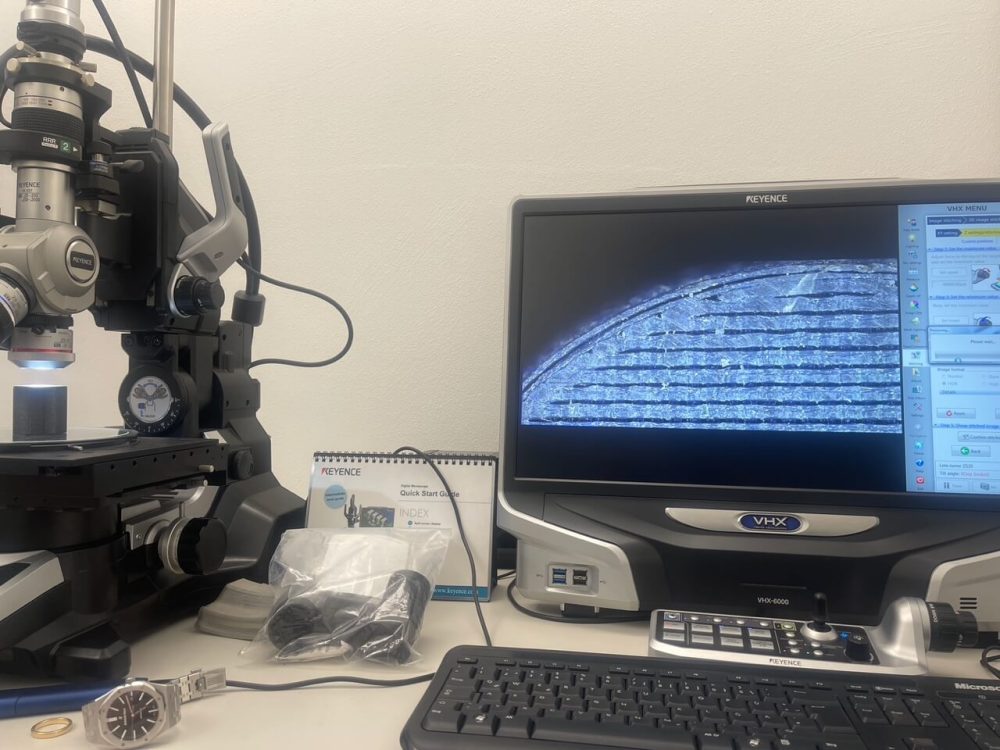

Nanoparticles are arranged on the surface in several thin layers self-organizing, providing highly stable and comprehensive protection. Typical layers can range from 2 µm to 10 µm, and their adhesion to the substrate can be mechanical and covalent type (chemical).

Furthermore, its formulation and process allow for the inclusion of engineered nanomaterials for adding extra properties to the coating, such as increased surface heat transmission, enhanced hydrophobicity, fluidodynamics properties, electrical conductivity, etc.

NANOPROM develops its proprietary products with full respect for health and the environment. All the components used for Polysil® have been subjected to toxicological and environmental controls.

In addition to that, the top-level safety of our nanotechnology-based products is ensured by numerous severe tests passed before introducing them to the market.

In a nutshell, all Polysil® family products are guaranteed health and environmental protection for the following reasons:

- The starting components are non-toxic.

- Only components bonded in nanolayers are used.

- The spray drops are not breathable.

- The nano components are attached to the surface without delamination or particulate release.

Our numbers

1000 EUROPE’S FASTEST GROWING COMPANIES 2022

Products & Services

- Polysil® anticorrosion coating: Due to its composition and its hydrophobicity, chemical inertness, and surface hardness characteristics, Polysil® is inherently corrosion resistant. With only 10 microns of coating on the aluminum, Polysil® provides over 240 hours of salt spray resistance. Thanks to its film properties, Polysil® is also suitable as a corrosion protection treatment for additive manufacturing parts.

- Ultra-lightweight coating: the application of the entire coating cycle (primer, paint, and clearcoat) on carbon composite weighs just 40g/m2

- Polysil® Thermal: The finely dispersed graphene nanoplatelets enable the Polysil® matrix to greatly enhance heat exchange (irradiation and surface conduction), boosting the thermal performance of the substrate.

- Polysil® Thermal Shield: NANOPROM has developed Polysil® TSR (Thermal Shield Resin). It is a resin-based on amorphous silicon, which offers excellent resistance to high temperatures and low thermal conductivity value (0,050 W/mK), which enables the manufacture of Carbon-TSR composites that have excellent heat resistance (working temperature over 600°C and resistance up to 1800°C).

- Aerodynamics drag reduction: Polysil® can be made with different surface tension values up to superoleophobicity, Polysil® coating allows an average reduction of Cx (drag coefficient) of about 0.8%.

Certifications

-

ISO 9001

-

ISO 14000

-

AS/EN 9100

Top Clients served by the company

-

Aerospace and Defense companies (under NDA)

-

F1 Teams (under NDA)

-

Fe Teams (under NDA)

-

Mahindra Racing

-

WEC Teams (under NDA)

-

Unical