BLACKS S.r.l.

Contacts

Description

BLACKS was created in November 2011 by a small group of young but experienced and passionate specialists who aim to focus on the design, prototype, and manufacturing of advanced composite materials components.A solid network of contacts, technical and technological skills, strong innovation commitment, and long-lasting partnerships are the fundamental tools that have led Blacks to achieve rewarding goals, training a team that today has 60 young, motivated, and highly skilled people.

Company history has grown steadily, cooperating with prestigious clients on demanding projects while expanding its technical potentialities and enhancing its production capabilities.

With a forward-thinking strategy and continuous improvement in technology and innovation, Blacks stands out by providing the highest quality products and complete services.Our agile and efficient structure can optimize every single process step.

We meet different requirements and keep a flexible and streamlined production flow, from incoming raw materials to final inspection.

At Blacks, manual skills and attention to detail combine with engineering skills, prototyping, and series production.

Our numbers

Products & Services

- Advanced composite parts production

In our production process:

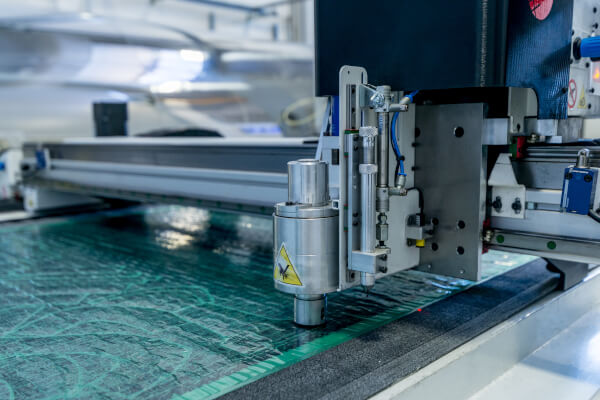

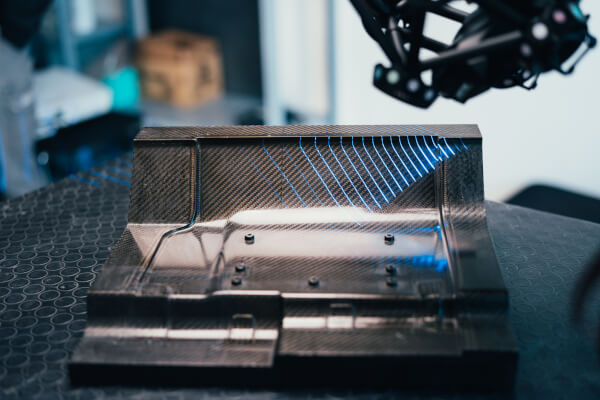

We start from impregnated composite materials, woven cloth, or uni-directional fibers previously soaked with resin. We machine-cut different shapes. We lay them up on a mold.

Sometimes together with core or other materials according to engineering design. We wrap everything in a vacuum-sealed pack. We cure the part in an autoclave with a computer-controlled cycle that may have different curing parameters according to resin characteristics.

- Engineering

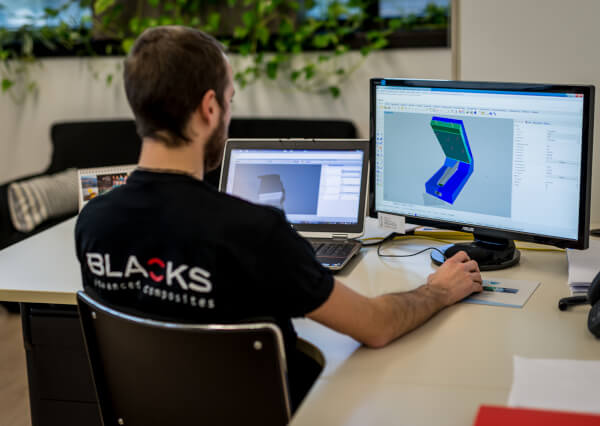

Our critical skills and distinctive curiosity enable us to face innovative and demanding projects, offering our customers reliable support. The design strategy follows a seamless path: the shape of the component has improved with 3D CAD tools conforming to customer specifications and requirements. Mould study and layup design fully integrated with the final part of the project target, within technological constraints. Run multi-process simulations to evaluate and select the most effective process.

- Modelling

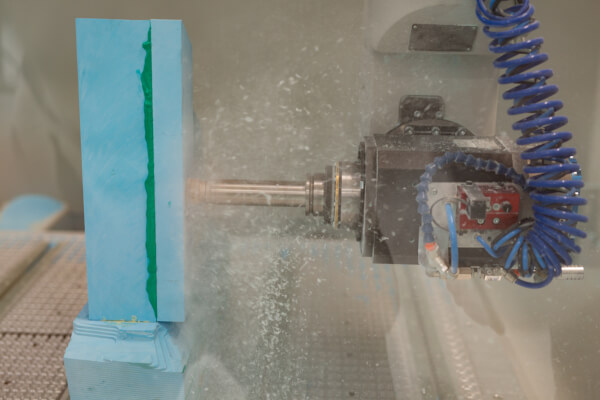

The 300 SQM modeling department supports technical specialists to ease molds and patterns design and development. A 5-axis CNC workstation can offer exceptional processing accuracy and high productivity.

- 3D-LAB

The Blacks 3D-Lab was established in 2019 and has evolved ever since then. Today shows that blending different technologies boost production performance and innovation.

The 3D-Lab provides printers based on different additive manufacturing technologies.

3D printing versatility is a great advantage: ranging from rapid prototyping to direct molds production, thanks to polish surface finishing, up to hollow composite parts production.

- Quality control

To ensure customer satisfaction, Blacks pays special attention to product quality control.

The high-level competencies and investments in education and operating metrology resources allow a trustworthy final product validation. This process thus satisfies the last step of the vertical management of the production flow to the customer’s need satisfaction.

Main Markets

- Italy

- Europe

Certifications

- ISO 9001:2015 Quality management system

- ISO 14001:2015 Environmental management system

Top Clients served by the company

-

Blacks supplies top European motorsport brands and has established solid cooperations with aerospace innovative companies.

-

-

-

-