3D4MEC S.r.l.

Description

3D4MEC S.r.l., the first Italian company to develop and market specialized 3D printing systems for metals, was founded in 2016 and is part of the group of companies headed by Ivano Corsini, an entrepreneur with more than 35 years ’ experience in the mechatronics and manufacturing sectors.

The years spent within the metal additive manufacturing sector combined with the years matured in the mechanical sector have empowered Ivano Corsini to develop a productive method, CorSystem, a superfast 3D printer for mechanics.

3D4MEC produces specialized machines for the process of specific alloys, customized for the production needs of every single customer, to optimize performance and make production with additive manufacturing the most efficient and cost-effective possible.

3D4MEC produces, upon order, two different specialized systems of 3D printing for metals, customized to the production needs of each customer. 3D4STEEL and 3D4BRASS.

Our numbers

Products & Services

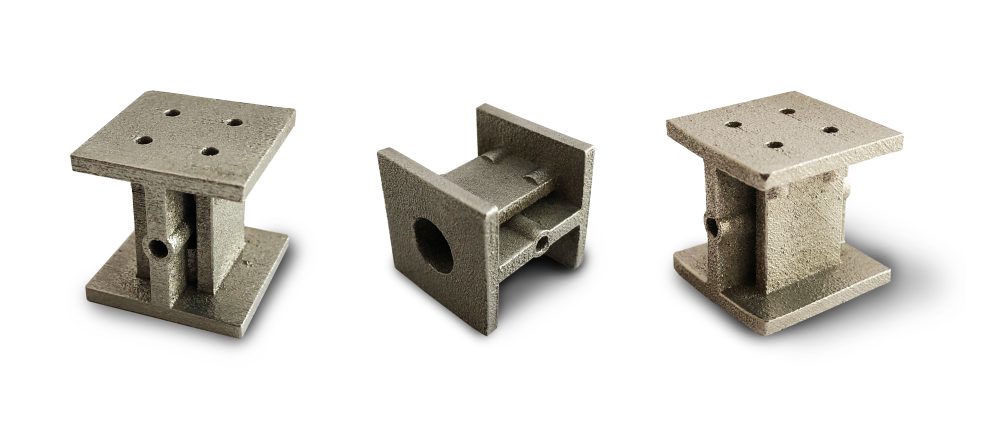

3D4STEEL: First 3D printer specialized in the process of steel :

- Automatic system for recycling unused powder

- Specialized system for steel powder distribution

- Owner of open software for reduction of costs

- Certification for eco sustainable filter disposal

- Sole use of self produced nitrogen

- Remote control via mobile app and desktop

In Brief: Compared to other metal additive generalist and multi-material technologies, 3D4STEEL, thanks to its specialization in processing steel alloys, permits the production of complex pieces at the lowest cost possible with maximum mechanical properties and performance suitable to mechanical applications.

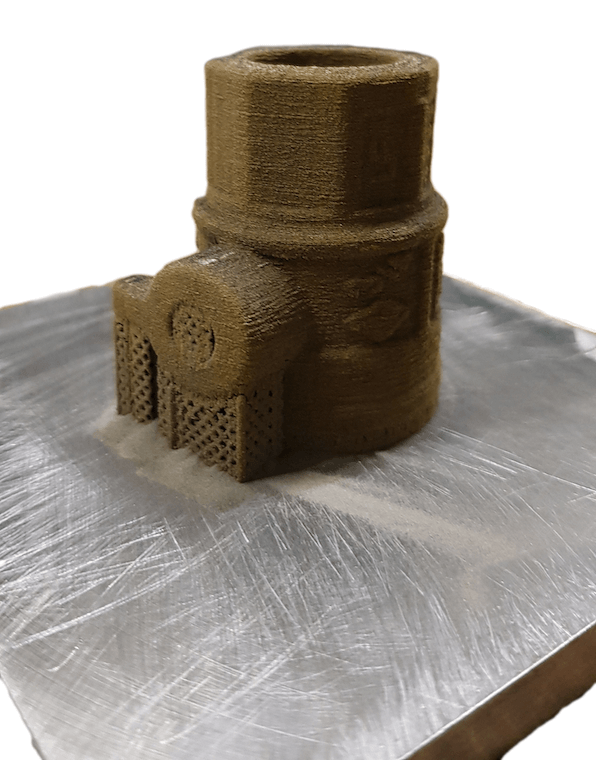

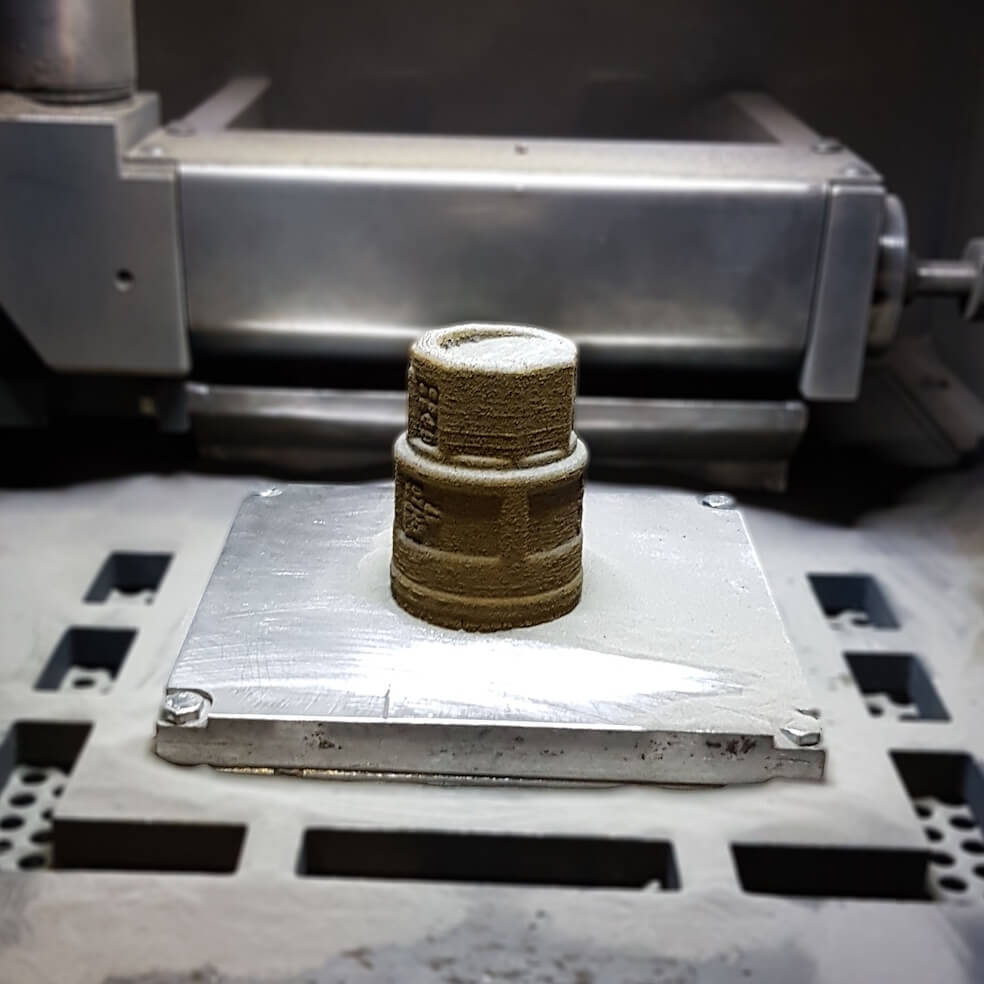

3D4BRASS First 3D printer in the world for production of brass components:

- Automatic system for recycling unused powder

- Specialized system for brass powder distribution

- Optical chain designed in function of high reflective materials

- Owner of open software for reduction of costs

- Certification for eco sustainable filter disposal

- Sole use of self produced nitrogen

- Remote control via mobile app and desktop

In Brief: Compared to traditional solutions for the production of brass components, 3D4BRASS allows 3D printing production in 3D directly in brass, without intermediary steps, guaranteeing.

- Maximum freedom of geometric construction

- Reduction of prototype costs

- Reduction of prototype flow.

On the whole eliminating scraps waste and costs related to storage

New Powder & Process Development:

In case we are missing a crucial material on our catalog that the customer wants, 3D4Mec offers a service of research & development of new alloys p 3D printers for such new materials.

- Chemical composition target;

- Chemical characterization;

- Powder production and calibration;

- Parameter development;

- Chemical analysis;

- Final 3D printing parameter set;

Main Markets

- Italy

- Europe

- North America