CRP TECHNOLOGY S.r.l.

Contacts

Description

Since 1996 CRP TECHNOLOGY has invested in the potential of 3D printing to become the first company to pioneer additive manufacturing in Europe.

We empowered AM technology with the research, development, and creation of reinforced composite materials – Windform – for the most demanding industries.

The revolution among the stars.

In the last decades, our high-performance composites are enhancing Aerospace key-leaders to reach their goals by manufacturing both space-ready functional prototypes and flight-proven accurate and reliable components.

Our Aerospace specialists will assist your design experts in getting the best results from your additive manufacturing concepts, including improvements to reduce mass, weight, costs, and lead times while enhancing safety-critical space-approved components.

Today CRP TECHNOLOGY is the unique partner of those looking for fresh thinking and innovative solutions in the additive field for the world of Aerospace, Defense, UAV, Motorsport, Automotive, Robotics, and other advanced industrial sectors.

________________

Thank you for downloading our White Paper, please click here.

Our numbers

Products & Services

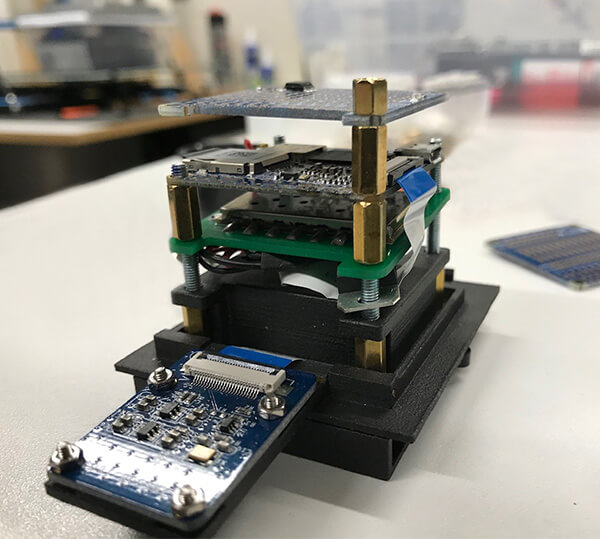

- 3D printed structural components for small satellites

The company specializes in functional, space-ready products such as CubeSats and pocketqubes, nanosat deployers.

Windform materials enhance space applications that require the highest fidelity, small sections, and lightweight.

- 3D printed wind tunnel models

Complete wind tunnel mockups capable of simulating different configurations of flight modes; scaled models where to test aero design solutions and high speed.

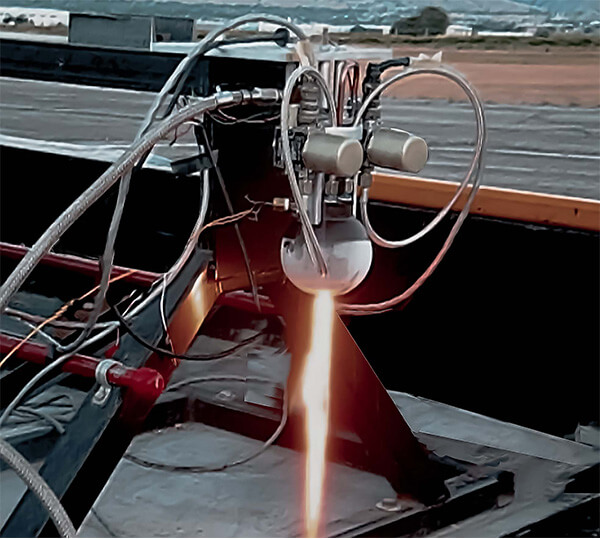

- 3D printed functional drone parts

A ready to use UAV / UAS body and arms for industrial and multipurpose tasks; performing flight and landing tests during prototyping, product development, and in real life and extreme weather conditions.

- 3D printed aviation applications

Windform’s high mechanical characteristics provide the manufacturing of functional, robust components suitable to resist and last in the most delicate missions.

Main Markets

CRP TECHNOLOGY operates in the following areas:

- EUROPE

- Region Gulf Cooperation Council (GCC – Kingdom of Saudi Arabia, Kingdom of Bahrain, United Arab Emirates, State of Kuwait, Sultanate of Oman, Qatar)

- NORTH AMERICA

- MIDDLE EAST

- FAR EAST

Certifications

CRP TECHNOLOGY is highly committed to quality management

- ISO 9001:2015 quality management system

- EN 9100:2018 quality management system

Product quality:

- Windform materials have passed NASA (ASTM E-595-07), JAXA, and European Space Agency (ESA TEC-QTE 7171) outgassing screening standard

- FAR 25.853 and 45° Bunsen burner test compliant

- HB classification and V-0 rate at flammability tests UL 94

- Vacuum ultraviolet (VUV)

Top Clients served by the company

-

LEONARDO COMPANY

-

GAUSS s.r.l

-

ALBA ORBITAL

-

HEXADRONE

-

PARROT

-

TETON AEROSPACE, LLC

-

MINI-CUBES, LLC

-

LABORATOIRE INTERUNIVERSITAIRE DES SYSTÈME ATMOSPHÉRIQUE

-

FLYING-CAM

-

Additional organisation/customers cannot be quoted as the supply is covered by NDA